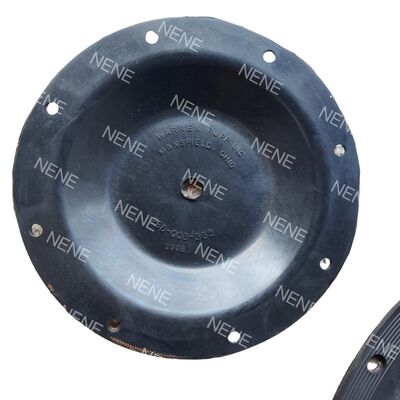

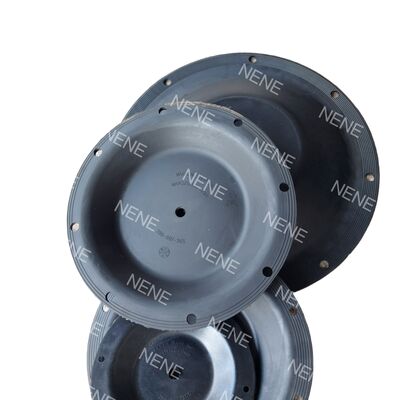

Description du produit:

Ce produit est un diaphragme de remplacement haut de gamme spécialement conçu pour une large gamme de pompes à diaphragme à air de qualité industrielle.Chaque diaphragme est soigneusement fabriqué avec des matières premières de haute qualité., offrant une flexibilité, une durabilité et une durée de vie exceptionnelles.

Conçus pour maintenir le fonctionnement continu et efficace de votre pompe à diaphragme, ces diaphragmes aident à minimiser les coûts d'entretien et à réduire les temps d'arrêt opérationnels,s'assurer que votre équipement reste fiable et productif.

Nous offrons plusieurs options de matériaux adaptés à différents environnements de travail, types de fluides et conditions de température.Déchets d'acier, du caoutchouc au fluorocarbone (FKM/Viton), du PTFE et du Santoprene, tous sélectionnés pour garantir des performances fiables même dans les applications les plus exigeantes.

Caractéristiques:

Notre produit offre une grande variété d'options de matériaux, y compris des substances de qualité professionnelle telles que le caoutchouc nitrile, le caoutchouc fluorocarboné, le PTFE et le santoprène.Ces matériaux sont soigneusement sélectionnés pour s'adapter à différents environnements chimiques et conditions de fonctionnement.

Les matériaux utilisés sont spécialement conçus pour offrir une excellente résistance chimique.et huiles, assurant une durabilité dans des environnements difficiles.

Conçus avec des propriétés mécaniques supérieures, les diaphragmes présentent une résistance et une élasticité élevées.même lors de mouvements fréquents.

Avec une large tolérance à la température, les différentes options de matériaux peuvent accueillir un large éventail de températures de fonctionnement, allant de niveaux extrêmement bas à des niveaux élevés,les rendant polyvalents pour de nombreuses applications.

Le processus de fabrication utilise des moules de précision pour obtenir des dimensions précises, assurant un ajustement exact avec des pompes à diaphragme de plusieurs marques et modèles.Cette précision permet un fonctionnement optimal et une compatibilité.

La conception structurelle optimisée réduit la concentration de contraintes, ce qui augmente considérablement la durée de vie du diaphragme.et la fréquence de remplacement diminue.

En outre, la conception conviviale facilite l'installation et le remplacement.minimiser les temps d'arrêt des équipements et améliorer l'efficacité opérationnelle globale.

Paramètres techniques:

| Compatibilité de la pompe |

Wilden, Yamada, Graco, et ainsi de suite. |

| Certification |

FDA, RoHS sont disponibles |

| Matériel |

NBR / FKM / PTFE / Santoprène |

| Résistance chimique |

Résistant aux huiles, aux acides et aux solvants |

| Température de fonctionnement |

-20°C à +150°C |

| Emballage standard |

1 pièces par boîte |

Ce diaphragme de soupape à impulsion est un accessoire essentiel pour la réparation du diaphragme, parfait comme kit de réparation du diaphragme ou kit de diaphragme pour l'entretien et l'entretien de votre équipement de pompage.

Applications:

Industrie chimique

Ce secteur implique le transfert de divers réactifs chimiques, y compris des substances corrosives telles que les acides, les alcalis et les solvants.La manipulation de ces matériaux nécessite un équipement spécialisé capable de résister à la corrosion chimique..

L'électroplatement et le traitement de surface

Dans les procédés de galvanoplastie et de traitement de surface, la circulation et le transfert des solutions de galvanoplastie, ainsi que des acides et des alcalis, sont essentiels.Ces opérations nécessitent un contrôle précis pour assurer une couche uniforme et une qualité de surface.

Fabrication de peintures et d'encres

La production de peintures et d'encres implique le transfert de pigments, de résines, de solvants et de produits finis.Des techniques de manipulation efficaces sont essentielles pour maintenir la qualité et la consistance des matériaux..

Industrie de la céramique et des matériaux de construction

Cette industrie gère le transfert des glaces, des lisières et des matières premières céramiques.

Industrie du traitement de l'eau

Au sein du traitement de l'eau, les tâches comprennent le traitement des eaux usées, le dosage chimique et le transfert des boues.

Traitement des aliments et des boissons

Le transfert de matières de qualité alimentaire est un aspect clé de cette industrie, qui nécessite l'utilisation de matériaux spécifiques conformes pour garantir les normes de sécurité et d'hygiène.

Industrie pharmaceutique

La production pharmaceutique implique le transfert d'ingrédients, d'intermédiaires et de matières auxiliaires, et les réglementations strictes régissent ces processus pour maintenir la pureté et l'efficacité du produit.

Mines et métallurgie

Les secteurs de l'exploitation minière et de la métallurgie s'occupent du transfert de lisières, d'agents de flottation et de diverses solutions métallurgiques.La gestion efficace de ces substances favorise des taux de récupération élevés et l'optimisation des processus.

Industrie du papier

Dans l'industrie du papier, le transfert de pâte, de revêtements et d'additifs chimiques est crucial pour la fabrication de produits en papier de qualité.Les systèmes de transfert coordonné aident à obtenir des résultats de production cohérents.

Assistance et services:

Notre produit est soutenu par une équipe technique dédiée engagée à assurer des performances optimales et une longévité.et des ressources de dépannage pour vous aider à manipuler et à utiliser correctement le diaphragme.

L'assistance technique comprend l'assistance à la sélection des produits, aux vérifications de compatibilité et à l'optimisation des performances pour répondre aux exigences spécifiques de votre application.Nos experts sont disponibles pour vous guider tout au long du processus d'installation, contribuant à éviter les problèmes communs et à maximiser l'efficacité.

En outre, nous offrons des services de réparation et de remplacement afin de minimiser les temps d'arrêt et de maintenir la fiabilité du système.Des recommandations d'entretien régulières et des intervalles de service sont fournis pour prolonger la durée de vie du diaphragme de la vanne à impulsions et prévenir les pannes inattendues.

Pour des applications complexes ou personnalisées, notre équipe d'ingénieurs peut collaborer avec vous pour développer des solutions et des améliorations sur mesure.Nous nous engageons à fournir un soutien et des services de haute qualité qui garantissent que votre diaphragme de valve d'impulsion fonctionne en douceur et efficacement dans votre collecteur de poussière ou système pneumatique.

Emballage et expédition

Emballage et expédition du produit pour le diaphragme de soupape à impulsions

Le diaphragme de la soupape de pouls est soigneusement emballé pour s'assurer qu'il vous parvient en parfait état.Chaque diaphragme est scellé individuellement dans du plastique de protection pour éviter la contamination et les dommages pendant le transportLes diaphragmes scellés sont ensuite placés dans des boîtes robustes et rembourrées conçues pour absorber les chocs et les vibrations.

Pour les commandes en vrac, les diaphragmes sont organisés soigneusement dans des cartons avec une étiquette claire pour une identification et une manipulation faciles.Tous les matériaux d'emballage utilisés sont respectueux de l'environnement et respectent les normes internationales de transport maritime.

L'expédition est effectuée par des services de messagerie fiables avec des options de livraison standard ou accélérée.et les clients reçoivent des informations de suivi lors de l'expédition.

Nous vous recommandons d'inspecter le colis immédiatement après la livraison et de nous signaler tout dommage dans les 48 heures pour assurer une résolution rapide.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!