Description du produit:

Ce produit sert de diaphragme de remplacement haut de gamme, spécialement conçu pour une large gamme de pompes à diaphragme pneumatiques de qualité industrielle.Chaque diaphragme est soigneusement fabriqué avec des matières premières de haute qualité.Ces caractéristiques garantissent le bon fonctionnement et l'efficacité de votre pompe à diaphragme,contribuant à minimiser les coûts de maintenance des équipements et à réduire les temps d'arrêt.

Pour s'adapter à différents environnements opérationnels, types de fluides et gammes de températures, nous offrons plusieurs choix de matériaux.Notre sélection comprend des matériaux de qualité professionnelle tels que le caoutchouc nitrile (NBR)Ces options sont conçues pour fournir des performances fiables même dans les conditions les plus difficiles.

Caractéristiques:

Options de matériaux multiples:Nos diaphragmes sont disponibles dans une variété de matériaux de qualité professionnelle, y compris le caoutchouc nitrile, le caoutchouc fluorocarboné, le PTFE, le santoprène, et plus encore.Ces options sont adaptées aux différents milieux chimiques et aux différents environnements de travail, assurant la compatibilité et la durabilité.

Excellente résistance chimique:Fabriqués à partir de matériaux spécialement préparés, ces diaphragmes offrent une résistance exceptionnelle à la corrosion causée par un large éventail de produits chimiques tels que les acides, les alcalis, les solvants et les huiles.les rendant idéales pour des applications chimiques agressives.

Propriétés mécaniques supérieures:Conçus avec une résistance élevée et une élasticité exceptionnelle, ces diaphragmes conservent leur forme et offrent des performances fiables même sous des mouvements réciproques fréquents.assurer un fonctionnement et une durabilité constants.

Large plage de température:Grâce à plusieurs choix de matériaux, les diaphragmes peuvent fonctionner efficacement sur une large plage de températures, de très basses à hautes températures, pour répondre à diverses exigences industrielles.

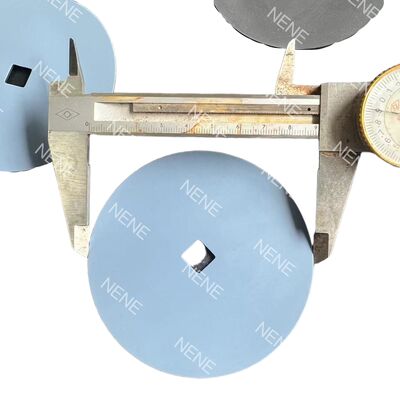

Processus de fabrication de précision:Fabriquées à l'aide de moules de précision, ces diaphragmes ont des dimensions précises qui garantissent un ajustement parfait avec une large gamme de marques et de modèles de pompes à diaphragme, assurant une intégration transparente.

Longue durée de vie:La conception optimisée réduit les points de concentration des contraintes, allonge considérablement la durée de vie du diaphragme et diminue la fréquence des remplacements, réduisant ainsi les coûts d'entretien.

Installation et remplacement faciles:Dotés d'une conception conviviale, ces diaphragmes permettent une installation et un remplacement rapides et simples, réduisant ainsi le temps d'arrêt de l'équipement et améliorant l'efficacité opérationnelle.

Paramètres techniques:

| Emballage standard |

1 pièces par boîte |

| Matériel |

NBR / FKM / PTFE / Santoprène |

| Certification |

FDA, RoHS sont disponibles |

| Température de fonctionnement |

-20°C à +150°C |

| Résistance chimique |

Résistant aux huiles, aux acides et aux solvants |

| Compatibilité de la pompe |

Wilden, Yamada, Graco, et ainsi de suite. |

Applications:

L'industrie chimique consiste à manipuler et à transférer un large éventail de réactifs chimiques, y compris les substances corrosives telles que les acides, les alcalis et divers solvants.qui nécessitent un équipement spécialisé pour assurer un traitement sûr et efficace.

Dans les procédés de galvanoplastie et de traitement de surface, la circulation et le transfert des solutions de galvanoplastie, ainsi que des acides et des alcalis, sont essentiels.Ces matériaux sont essentiels pour obtenir les propriétés de surface souhaitées sur les pièces métalliques.

La fabrication de peintures et d'encres nécessite le transfert de différents composants tels que les pigments, les résines, les solvants et les produits de peinture finaux.Une manipulation prudente est essentielle pour maintenir les normes de qualité et de sécurité des produits.

L'industrie de la céramique et des matériaux de construction s'occupe du transfert de glaçures, de lisières et de matériaux céramiques bruts.Ces substances font partie intégrante de la production de produits céramiques finis et de matériaux de construction.

Dans l'industrie du traitement de l'eau, les processus comprennent le traitement des eaux usées, le dosage chimique et le transfert des boues.Ces activités sont essentielles au maintien de la qualité de l'eau et de la conformité environnementale.

Le secteur alimentaire et des boissons exige le transfert de matériaux de qualité alimentaire à l'aide d'équipements spécialement conformes.Cela garantit que toutes les substances répondent aux normes de santé et de sécurité propres à la consommation.

L'industrie pharmaceutique s'occupe du transfert des ingrédients pharmaceutiques, des intermédiaires et des matériaux auxiliaires.

Dans le secteur minier et de la métallurgie, le transfert de lisières, d'agents de flottation et de solutions métallurgiques est un élément fondamental des opérations de transformation et d'extraction.

Enfin, l'industrie du papier implique le transfert de pâte, de divers revêtements et d'additifs chimiques nécessaires à la production et à la finition du papier.

Assistance et services:

Notre produit Pulse Valve Diaphragm est soutenu par une équipe de support technique dédiée qui s'engage à assurer des performances et une longévité optimales.Nous offrons des services complets, y compris des conseils d'installation, une aide au dépannage et des recommandations d'entretien pour vous aider à tirer le meilleur parti de votre diaphragme de valve pulsée.

Nos experts sont disponibles pour vous fournir des informations détaillées sur les spécifications du produit, la compatibilité et les procédures de remplacement.Nous offrons également des séances de formation et une documentation technique pour doter votre équipe de maintenance des connaissances nécessaires à une manipulation et à une maintenance efficaces.

En plus de l'assistance, nous fournissons des services à valeur ajoutée tels que la conception de diaphragmes personnalisés, des conseils sur la sélection des matériaux et des analyses du cycle de vie pour répondre à vos besoins spécifiques.Notre objectif est de fournir des solutions fiables qui améliorent l'efficacité et la durabilité de vos systèmes de valves à impulsions.

Pour toute question technique ou demande de service liée au diaphragme de soupape à impulsion, veuillez consulter nos ressources en ligne et nos manuels d'utilisation,qui offrent des instructions étape par étape et des conseils pour vous aider rapidement.

Emballage et expédition

Emballage et expédition du produit pour le diaphragme de soupape à impulsions

Le diaphragme est soigneusement emballé pour s'assurer qu'il arrive en parfait état.Chaque diaphragme est enveloppé individuellement dans un plastique de protection pour éviter tout dommage ou contamination pendant le transportLes diaphragmes enveloppés sont ensuite placés dans des boîtes robustes et rembourrées conçues pour absorber les chocs et les vibrations.

Pour les commandes en vrac, les diaphragmes sont emballés en toute sécurité dans des cartons plus grands avec des matériaux de rembourrage appropriés pour éviter le mouvement et le frottement entre les articles.Tous les matériaux d'emballage sont choisis pour être durables et résistants à l'humidité afin de maintenir l'intégrité du produit tout au long du processus d'expédition.

L'expédition est traitée par des transporteurs fiables avec des options de suivi disponibles. Nous assurons l'expédition et la livraison en temps opportun, avec des options d'expédition accélérée si nécessaire.Chaque envoi est clairement étiqueté avec les détails du produit et les instructions de manutention pour faciliter le dédouanement en douane et une manipulation correcte.

En résumé, nos procédures d'emballage et d'expédition sont conçues pour protéger le diaphragme de la valve de pulsation contre les dommages, la contamination et les facteurs environnementaux,vous assurer que vous recevez un produit de haute qualité prêt à être utilisé immédiatement.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!